We are a professional manufacturer of Stainless Steel Filter Disc products, providing high-performance filtration solutions for diverse industries. Engineered for durability and reliability, our Stainless Steel Filter Discs are designed to handle high temperatures, corrosive fluids, and demanding pressure conditions. These discs are widely used in chemical processing, pharmaceuticals, food production, and water treatment systems.

Material

Our Stainless Steel Filter Disc is made from high-quality stainless steel grades such as 304, 304L, 316, and 316L, ensuring excellent corrosion resistance and long-term performance. These discs are fabricated using woven mesh, sintered mesh, or perforated metal, and can be single-layer or multi-layered, depending on filtration precision requirements.

Common Sizes and Dimensions

We supply Stainless Steel Filter Discs in standard and custom sizes to meet various filtration needs:

- Diameter: 10 mm, 25 mm, 47 mm, 100 mm, 150 mm, or custom up to 600 mm

- Thickness: 0.5 mm to 3.0 mm

- Filtration rating: From 5 microns to 300 microns, depending on mesh count and material type

- Shapes: Round, oval, square, and special forms available upon request

These dimensions ensure compatibility with filter housings and industrial equipment across multiple sectors.

Mesh Count and Filter Precision

Stainless Steel Filter Discs are classified by mesh count and filtration accuracy.

- Mesh count range: 10 to 500 mesh

- Filtration accuracy: 5 to 200 microns

- Single-layer disc: Ideal for coarse filtration or support layers

- Multi-layer disc: Designed for fine filtration and increased strength

These variations allow customers to select the ideal filter disc for particle retention, flow rate, and durability.

Applications

Our Stainless Steel Filter Disc products are widely used in:

- Petrochemical refineries for gas and fluid filtration

- Pharmaceutical manufacturing to ensure product purity

- Food and beverage processing for hygienic particle removal

- Water treatment systems for sediment and debris capture

- Hydraulic systems as protective filtration layers

These filter discs are vital for protecting pumps, valves, and sensitive instruments in process lines.

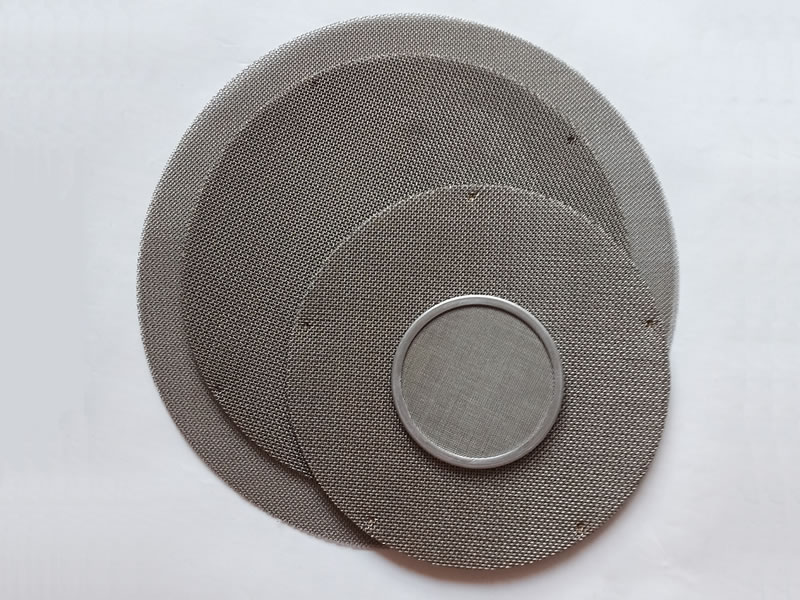

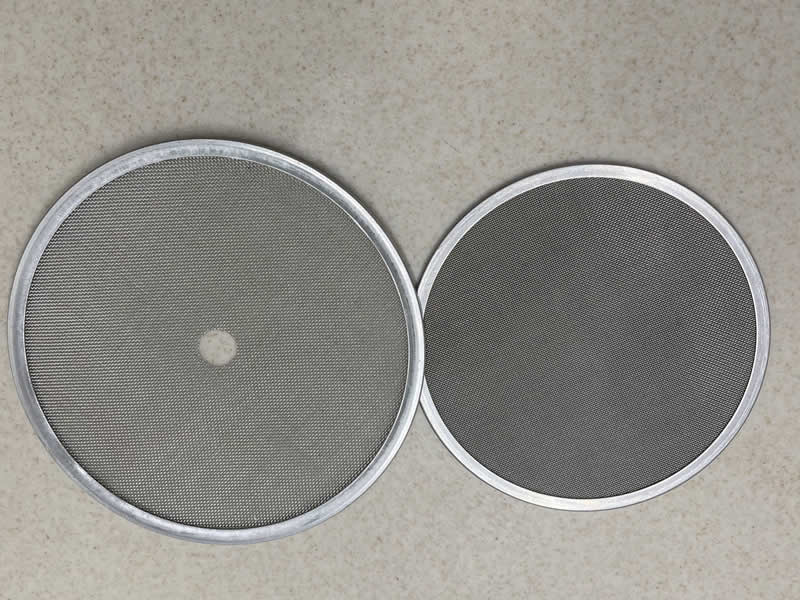

Edge Types

To enhance durability and easy installation, our Stainless Steel Filter Discs are available with:

- Plain edges

- Welded edges

- Aluminum or stainless steel framed edges

- Rubber-sealed rings for pressure-tight fittings

This flexibility supports various connection methods in filtration assemblies and cartridge systems.

Corrosion Resistance and Reusability

Thanks to stainless steel’s non-reactive properties, our Stainless Steel Filter Discs are resistant to:

- Acids and alkalis

- High-temperature steam and chemical vapors

- Mechanical wear and backflushing

They can be cleaned and reused multiple times, making them a sustainable and cost-effective choice for industrial operations.

Customization

As a professional manufacturer, we offer custom-made Stainless Steel Filter Discs to meet specific filtration challenges. We can accommodate:

- Custom diameters, thicknesses, and mesh types

- OEM branding or packaging

- Bulk quantities for industrial projects or distribution

Whether for high-flow filtration or fine particle separation, we provide tailored solutions with competitive pricing and fast lead times.