We are a professional manufacturer of Stainless Steel Sintered Mesh products, providing advanced filtration solutions for high-demand applications. Manufactured through vacuum sintering and lamination of multi-layer stainless steel wire cloth, our sintered mesh combines high strength, uniform pore structure, and excellent corrosion resistance. It is an ideal filtration medium in chemical processing, polymer systems, aerospace, power generation, and liquid-solid separation processes.

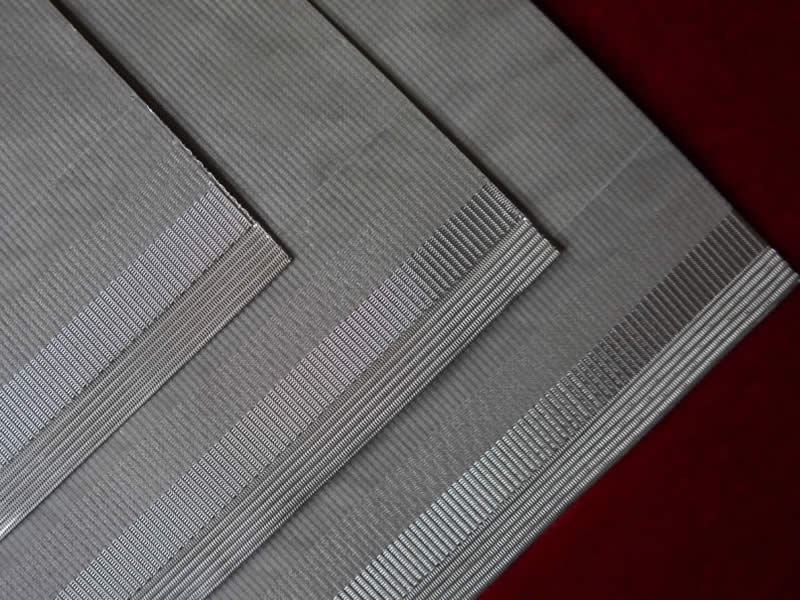

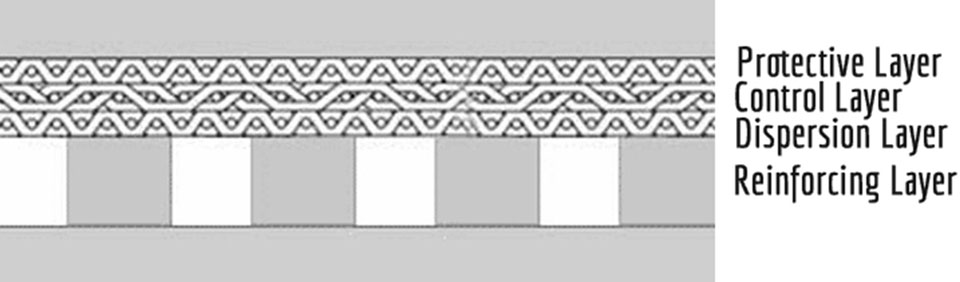

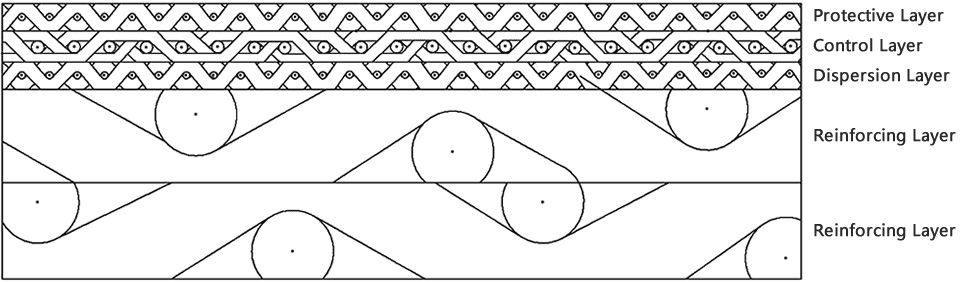

Construction and Layered Composition

Stainless Steel Sintered Mesh is typically built with three to five layers of wire mesh, permanently bonded through sintering and compression.

- Two reinforcing layers for mechanical support

- One dispersion layer to distribute flow evenly

- One precision filtration layer for particle capture

- One protective outer layer to guard the filtration mesh

This multilayer structure offers stability under high pressure and mechanical load, making it suitable for both surface and depth filtration.

Sizes and Standard Formats

We offer Stainless Steel Sintered Mesh in various sheet and roll dimensions to accommodate industrial equipment and fabrication needs:

- Standard sheet sizes: 500 × 1000 mm, 600 × 1200 mm

- Maximum sheet size: 610 × 1250 mm

- Thickness range: 0.27 mm to 1.7 mm depending on rating and layer structure

- Custom shapes: Discs, cylinders, cones, and pleated cartridges available upon request

All sheets are cut precisely and can be further processed into finished filter elements.

Filtration Ratings

Our Stainless Steel Sintered Mesh offers absolute filtration ratings ranging from 1 micron to 100 microns, with corresponding physical properties:

- Bubble pressure: From 12300 Pa (3 μm) to 630 Pa (60 μm)

- Air density: From 9 to 1000 L/dm²/min

- Porosity: Up to 87% depending on the layer structure

- Dirt holding capacity: Up to 33.97 mg/cm²

This precise performance data ensures reliable filtration across flow-sensitive and contaminant-critical systems.

Specifications by Nominal Rating

Each Stainless Steel Sintered Mesh can be classified by its nominal rating, control layer mesh count, permeability, and structural resistance:

- 2 μm: Mesh 325×2400, thickness 1.7 mm, permeability 38%, weight 8.4 kg/m²

- 5 μm: Mesh 200×1400, thickness 1.7 mm, permeability 38%, weight 8.4 kg/m²

- 10 μm: Mesh 165×1400, permeability 38%, resistance 7×105 cm

- 20 μm: Mesh 165×800, resistance 4×105 cm

- 40 μm: Mesh 50×250, initial bubble pressure 150–400 mm H₂O

This range supports applications requiring precision separation, uniform flow, and structural integrity.

Features

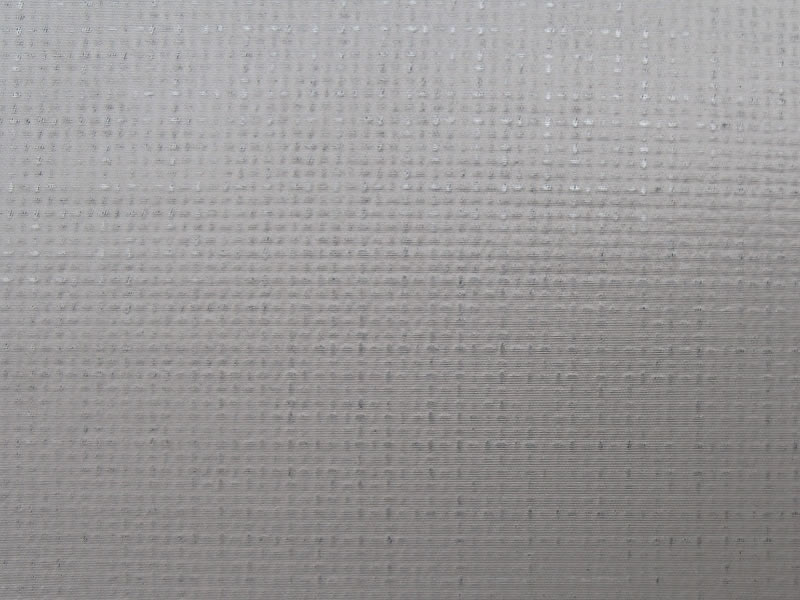

- Stable pore structure: The sintering process ensures pores are fixed and not altered during use.

- High mechanical strength: Reinforced layers enable operation under differential pressures and harsh conditions.

- Corrosion resistance: Manufactured from 316L stainless steel for excellent chemical compatibility.

- Temperature resistance: Performs reliably in environments up to 480°C.

- Reusability and easy cleaning: Back-flushable and ultrasonically cleanable for long-term cost savings.

- Customizable forms: Can be fabricated into cones, barrels, round discs, or pleated filter cartridges.

Applications

- Filter cartridges for polymers, fuels, and hydraulic systems

- Catalyst recovery in petrochemical plants

- High-pressure gas and steam filtration

- Backwash filters in water treatment facilities

- Pharmaceutical and food-grade process filters

It is especially favored where durability, precision, and cleanliness are mission-critical.

Customization and Quality Standards

- Custom pore size, layer configuration, and sheet thickness

- OEM disc or cartridge formats

- Quick turnaround and bulk order capabilities

- Compliant with ISO 9001, ASTM, and EN filtration standards