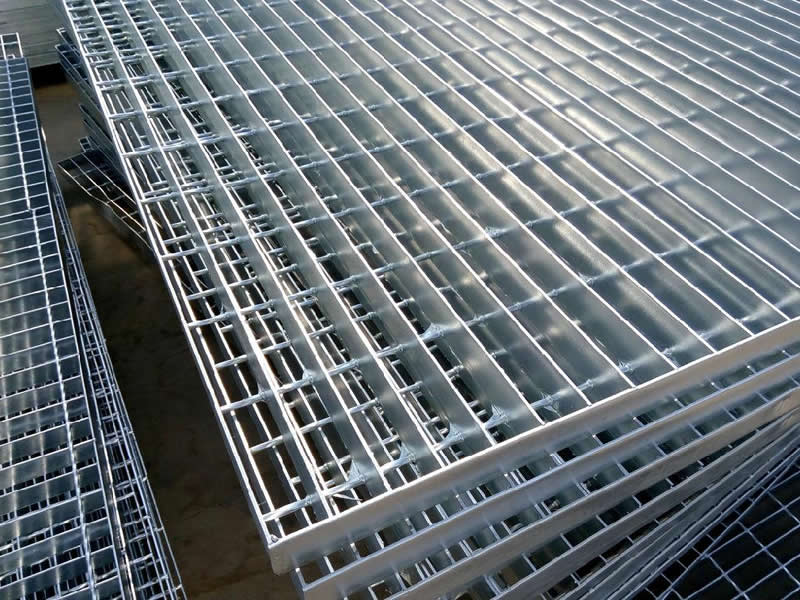

Bangyi is a professional manufacturer of Steel Grating, offering high-strength, corrosion-resistant grating solutions for industrial, commercial, and infrastructure applications. Our steel grating products are engineered using advanced hydraulic resistance welding or pressure locking methods, providing robust support and durability for flooring, walkways, platforms, and trench covers.

Materials and Finishing Options

Steel Grating is manufactured from carbon steel (Q235, ASTM A36, A1011, A569) or stainless steel for environments requiring corrosion resistance. Surface treatments include self-color (black steel), painted finish, or hot-dip galvanizing in accordance with standards like GB/T13912-2002, ASTM A123, and BS729.

Types of Steel Grating

- Plain Flat Bar Grating – Smooth surface for general walking applications.

- Serrated Grating – Anti-slip surface ideal for wet or oily environments.

- I-Bar Grating – Lighter in weight, offering strength and economy.

- Serrated I-Bar Grating – Combines safety and lightweight strength.

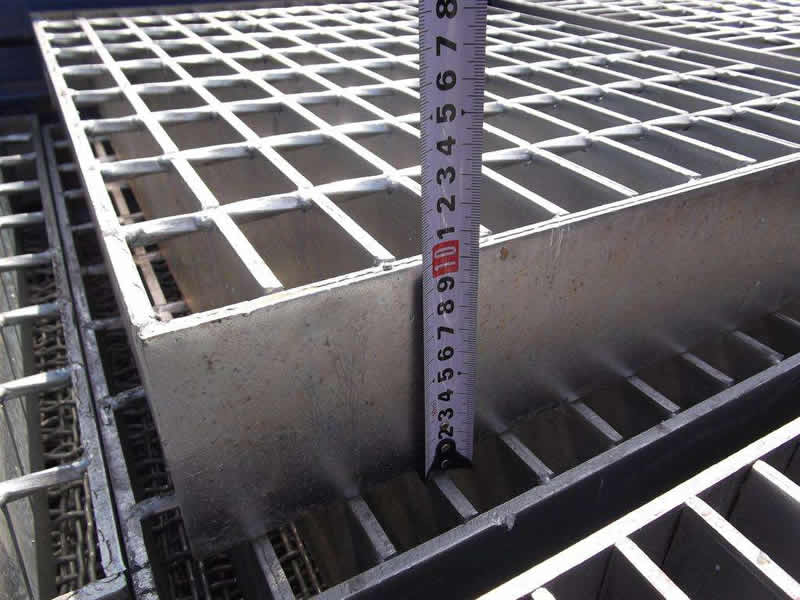

Bearing Bar Dimensions

Steel Grating is made with bearing bars of various sizes, typically.

- Width: 20 mm, 25 mm, 30 mm, 32 mm, 40 mm, 45 mm, 50 mm, 60 mm, 75 mm

- Thickness: 3 mm, 4 mm, 5 mm, 6 mm, 7 mm, 10 mm

Standard US equivalents include:

1″×3/16″, 1¼”×3/16″, 1½”×3/16″, 1″×1/4″, etc.

Bearing Bar Pitch (Spacing)

- 12.5 mm, 25 mm, 30 mm, 33.5 mm, 34.3 mm, 35 mm, 37.5 mm, 40 mm, 60 mm

Cross Bar Pitch (Spacing)

- Standard spacing includes 38 mm, 50 mm, 76 mm, 100 mm, and 101.6 mm

Panel Sizes

Steel Grating panels are commonly fabricated in the following dimensions:

- 1000 mm × 5800 mm

- 1000 mm × 6000 mm

- Custom sizes are available based on project specifications.

Production Methods

- Welded Grating: Bars are joined at intersections with 200-ton hydraulic resistance welding for high strength.

- Pressure Locked Grating: Mechanically locked under pressure without welding for clean aesthetics and rigidity.

Surface Treatments

- Self-Color: No coating; suitable for painting or indoor use.

- Painted: Enhanced aesthetic and rust resistance.

- Hot-Dip Galvanized: Long-term outdoor durability with zinc coating per ASTM A123 or GB/T13912-2002.

Standards and Compliance

- China: YB/T 4001.1-2007, GB700-88

- USA: ANSI/NAAMM MBG531, ASTM A36

- UK: BS4592, BS4360

- Germany: DIN24537, DIN17100-80

- Australia: AS1657, AS3679

Applications

- Industrial platforms, walkways, operating floors, and mezzanines

- Trench covers, drainage grates, and manhole lids

- Stair treads, footbridges, maintenance areas

- Ceilings, fencing, screens, and safety barriers

- Public infrastructure like airports, ports, and factories

Steel Grating Introduction

| Bearing Bar Type | Flat Bar | I Bar | Serrated Bar |

| Cross Bar Type | Twisted Bar | Round Bar | Flat Bar |

| Production Process | Welded | Pressure Locked | |

| Surface Treatment | Self-Colour | Galvanized | Painted |

| Application | Platform | Walkway&Floor | Trench Cover |

| Suspended Ceiling | Barrier Fence | Steel Stair Treads |

Steel Grating Specification

Panel size available(black grating): 1000x5800mm or 1000x6000mm

| Bearing Bar Pitch | Cross Bar Pitch | Bearing BarSize (Width ×Thickness) | |||||

| 20×3 | 25×3 | 32×3 | 40×3 | 20×5 | 25×5 | ||

| 30 | 100 | G203/30/100 | G253/30/100 | G323/30/100 | G403/30/100 | G205/30/100 | G255/30/100 |

| 50 | G203/30/50 | G253/30/50 | G323/30/50 | G403/30/50 | G205/30/50 | G255/30/50 | |

| 40 | 100 | G203/40/100 | G253/40/100 | G323/40/100 | G403/40/100 | G205/40/100 | G255/40/100 |

| 50 | G203/40/50 | G253/40/50 | G323/40/50 | G403/40/50 | G205/40/50 | G255/40/50 | |

| 60 | 50 | G203/60/50 | G253/60/50 | G253/60/50 | G403/60/50 | G205/60/50 | G255/60/50 |

| Bearing Bar Bitch | Cross Bar Pitch | Bearing BarSize (Width ×Thickness) | |||||

| 32×5 | 40×5 | 45×5 | 50×5 | 55×5 | 60×5 | ||

| 30 | 100 | G325/30/100 | G405/30/100 | G455/30/100 | G505/30/100 | G555/30/100 | G605/30/100 |

| 50 | G325/30/50 | G405/30/50 | G455/30/50 | G505/30/50 | G555/30/50 | G605/30/50 | |

| 40 | 100 | G325/40/100 | G405/40/100 | G455/40/100 | G505/40/100 | G555/40/100 | G605/40/100 |

| 50 | G325/40/50 | G405/40/50 | G455/40/50 | G505/40/50 | G555/40/50 | G605/40/50 | |

| 60 | 50 | G325/60/50 | G405/60/50 | G455/60/50 | G505/60/50 | G555/60/50 | G605/60/50 |